Two separate initiatives, which have been backed by the European Innovation Council and the Good Fashion Fund respectively, aim to reduce the negative impacts of garment and textile manufacturing.

The textile and garment industry is estimated to be responsible for between 6% and 10% of global carbon emissions and about 20% of global clean water pollution from dyeing and finishing products. Waste is also a mounting problem. In the fashion industry alone, of the 80 to 100 billion tonnes of clothing produced a year, only 1% is recycled into new clothing, the rest ends up in incinerators or in landfill. The sector is also notorious for its long and tainted history of poor labour standards, particularly in the Global South.

A number of impact investors are working to turn the fast fashion and textile manufacturing industries around by backing sustainable companies and disruptive technologies.

Non-toxic biodegradable pigments

The European Innovation Council (EIC) has backed Sparxell, a Cambridge university spin-out, with a €1.9m grant to scale the production of its sustainable colourant technology, which can be used across a wide range of applications.

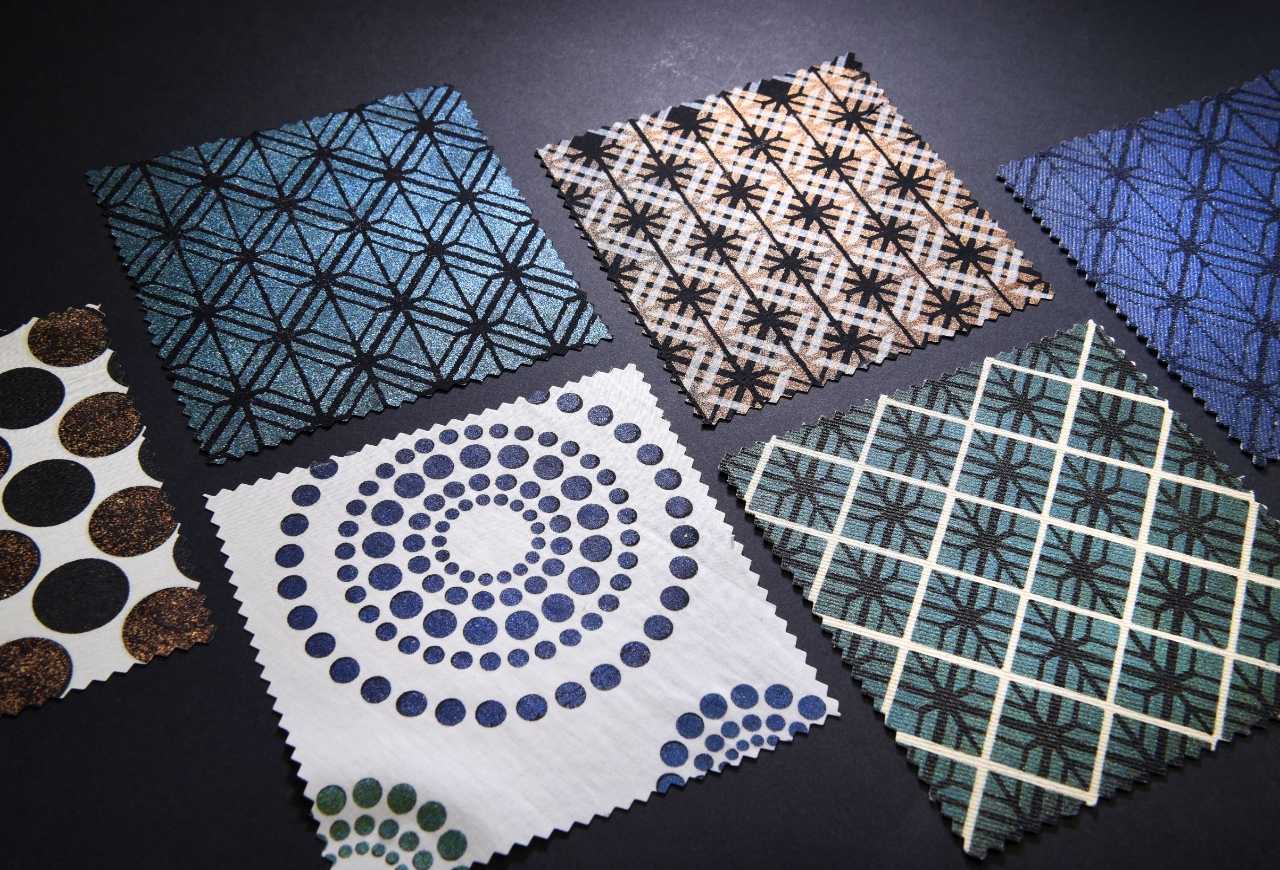

The textile industry currently uses more than 10,000 fossil-based chemicals in colouration processes but the company says its biodegradable pigments, which can be used in textile dyeing and printing, have been developed free of these chemicals. They are also said to significantly reduce energy and water consumption compared to conventional dyeing and printing methods.

The company also claims that its technology eliminates toxicity in human-contact applications such as cosmetics and food applications and can enable large-scale recycling and circularity across industrial sectors such as packaging and paint.

The technology works by transforming cellulose from readily available materials, such as wood pulp and agricultural waste, into vibrant colour solutions that the company claims exceed the performance of synthetic dyes in colour intensity and durability.

Expansion plans

To date, Sparxell has launched 25 fully funded pilot projects with global brands across a wide range of industrial sectors. It has also been part of LVMH’s startup accelerator programme, which has provided it with access to the luxury fashion conglomerate’s fashion brands, including Louis Vuitton, Christian Dior, Givenchy, and Loewe.

Looking ahead, Sparxell aims to double production capacity and establish production laboratories, positioning itself to capture a significant share of the growing $48bn (€42bn) colourants market, in which it said momentum is being accelerated by tightening regulations. These include the FDA’s recent announcements to ban artificial food colour dyes due to health concerns and the EU’s microplastics ban, which Sparxell said created significant market opportunities for its pigments.

Sustainable rug manufacturing

Impact Investor recently reported that the $19m Good Fashion Fund (GFF), initiated by the Laudes Foundation and Fashion for Good, had provided a $2m loan to K.K.P Fine Linen, an Indian manufacturer and exporter of bed linen and made-up products.

This month, the fund has announced a further and final investment into Sharadha Terry Products, an Indian manufacturer and exporter of high-quality bed and bath products under the Micro Cotton brand. The $1.75m loan will be used towards the installation of a tufting machine and accessories, which will be located at a new bath and area rugs unit in Metupalayam in the state of Tamil Nadu.

Reducing water use and pollution

The new rugs unit has an annual capacity of four million square metres and will primarily produce dope dyed polyester bath rugs and cotton bath rugs. Sharadha Terry said that compared to conventional rug manufacturing units, its new unit would reduce water consumption and eliminate the usage of hazardous chemicals, typically used in conventional dyeing, from its dyeing processes. This ambition will be supported by a dedicated effluent treatment plant that the company said will recover up to an estimated 98% of wastewater. The unit is also anticipated to create more than 200 jobs in the local region.

Sharadha Terry, which started to use wind power in 2008 and expanded into solar in 2015 with India’s largest rooftop solar installation, claims to source 100% of its energy from renewable sources toady with a combined generation capacity of 5.1 MW of wind energy and 10.1 MW of solar energy.

Vikram Krishna, managing director, said: “This investment enables us to expand our product portfolio into bath and area rugs while reinforcing our deep commitment to environmental stewardship and community development. At Sharadha, we believe that growth and responsibility go hand in hand and with this support, we are building one of India’s most resource-efficient rug manufacturing units, powered by clean energy and operated by local talent.”

GFF is managed by Dutch impact investment firm FOUNT, which confirmed that since its first sustainable fashion fund is fully invested, it is aiming for a first close of a second fashion fund by the end of 2025 with a final close by the end of 2026.